| Price £ | Brand | Type | Filament |

|---|---|---|---|

| 13.97 | kexcelled | ABS | ABS Heat Resistance ±0.03mm 1kg (2.2lbs) White |

| 14.39 | Eryone | ABS | High Speed ABS ±0.03mm Rapid 30-600mm/s Hyper 1kg (2.2lbs) / Black |

| 14.99 | kexcelled | ABS | ABS Heat Resistance ±0.03mm 1kg (2.2lbs) Black |

| 15.19 | Eryone | ABS | High Speed ABS ±0.03mm Rapid 30-600mm/s Hyper 1kg (2.2lbs) Grey |

| 15.29 | Eryone | ABS | High Speed ABS ±0.03mm Rapid 30-600mm/s Hyper 1kg (2.2lbs) / Red |

| 15.99 | - | ABS | Kexcelled ABS Heat Resistance ±0.03mm 1kg (2.2lbs) Sky Blue |

| 15.99 | Belns Melns | ABS | ST64 Vintage Light Bulbs with E27 Edison Screw Cap Squirrel Cage Shaped Bulb 2700K Warm White Dimmable Pack of 6 |

| 15.99 | Creality | ABS | ABS Official Strong Bonding Overhang Performance ±0.03mm 1kg(2.2lbs)/ (Black) |

| 15.99 | Creality | ABS | ABS Official Strong Bonding Overhang Performance ±0.03mm 1kg(2.2lbs) (White) |

| 15.99 | esun | ABS | ABS+ Low Warping ABS Plus ±0.05mm 1kg (2.2lbs) 3D Printers Black |

| 15.99 | esun | ABS | ABS+ eABS+HS High Speed ABS Plus ±0.05mm 1kg (2.2lbs) 3D Speedy Printing |

| 15.99 | esun | ABS | ABS+ Low Warping ABS Plus ±0.05mm 1kg (2.2lbs) Cold White |

| 15.99 | esun | ABS | ABS+ Low Warping ABS Plus ±0.05mm 1kg (2.2lbs) 3D Printers Fire Engine Red |

| 15.99 | kexcelled | ABS | ABS Heat Resistance ±0.03mm 1kg (2.2lbs) Fire Engine Red |

| 15.99 | Kingroon | ABS | Pla ±0.03Mm High Speed 1kg (2.2lbs) Grey |

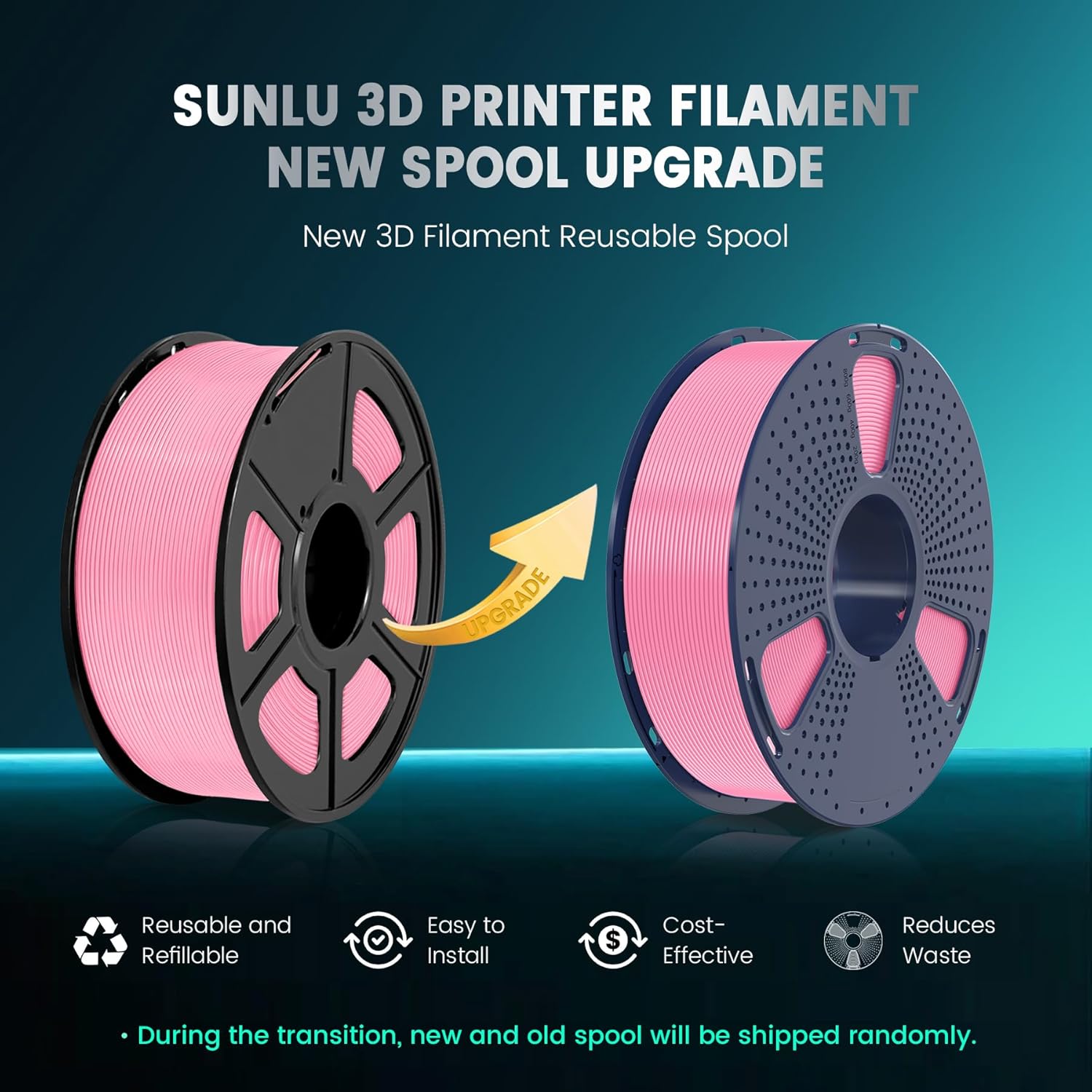

| 16.00 | Sunlu | ABS | ABS High Heat Resistant Reliable Functional Strength Impact Durable 0.9kg Black |

| 16.99 | Eryone | ABS | Engineering ±0.03mm ABS Plus Red 1kg (2.2lbs) |

| 17.59 | Creality | ABS | Official Hyper ABS Creality High-Speed Printing Heat Resistant Strong Durable ±0.03mm 1kg / (Grey) |

| 17.99 | Sunlu | ABS | ABS FDM 3D Printer 1kg(2.2lbs) ±0.02mm Red |

| 17.99 | Sunlu | ABS | ABS FDM 3D Printer 1kg(2.2lbs) ±0.02mm White |

| 17.99 | Sunlu | ABS | ABS FDM 3D Printer 1kg(2.2lbs) ±0.02mm Orange |

| 19.99 | Amolen | ABS | AMOLEN |

| 19.99 | esun | ABS | ABS+ Low Warping ABS Plus ±0.05mm 1kg (2.2lbs) Orange |

| 20.00 | Sunlu | ABS | ABS FDM 3D Printer 0.9KG ±0.02mm Black |

| 20.99 | Creality | ABS | Official Hyper ABS Creality High-Speed Printing Heat Resistant Strong Durable ±0.03mm 1kg / (White) |

| 20.99 | Creality | ABS | Official Creality Hyper ABS Grey High-Speed Printing Convenient Open High Impact Resistance 1kg Fit |

| 20.99 | Creality | ABS | Hyper ABS PLA White High-Speed Printing Convenient Open High Impact Resistance 1kg Fit |

| 20.99 | Creality | ABS | Official Hyper ABS Creality High-Speed Printing Heat Resistant Strong Durable ±0.03mm 1kg / (Black) |

| 20.99 | Eryone | ABS | Engineering ±0.03mm PP Black 900g |

| 20.99 | Eryone | ABS | ABS ±0.03mm PP White 900g |

| 25.99 | Qidi Tech | ABS | ABS Rapido 1kg (2.2lbs) Suitable Hyper Speed Printing Hyperly Resistant Red |

| 26.99 | Eono | ABS | Storage Bags Vacuum Kit Cleaning Drying Sealed 16 with Two Sizes Automatic Pumps/Desiccants/Humidity Indicator Cards/Clips |

| 28.99 | Qidi Tech | ABS | ABS Odorless 1kg (2.2lbs) Silver |

| 29.99 | esun | ABS | Flexible TPE High Elasticity TPE-83A ±0.05mm 1kg (2.2lbs) Black |

| 51.99 | Qidi Tech | ABS | Glass Fiber ABS ABS-GF25 Frosted Texture High Hardness Interlayer Bond Strength 1kg Black |